Comprehensive Guide to Wrenches: 8 Types Explained

Wrenches are essential tools in any toolkit, ranging from household repairs to heavy-duty industrial applications. They are designed to provide grip and mechanical advantage in applying torque to turn objects—typically fasteners such as nuts and bolts. Wrenches come in various forms, each specialized for different applications and tasks. Understanding the different types of wrenches and their uses will help in choosing the right tool for the job, whether for a professional mechanic, a handyman, or someone performing simple household tasks.

This article explores the general uses, advantages, and applications of wrenches, and highlights 8 key wrench types and the corresponding features and usages.

General Introduction to Wrenches

A wrench is used to turn rotary fasteners—like nuts and bolts—by gripping the fastener and allowing the user to apply torque. The size and design of wrenches vary depending on the type of fastener and the application. Many wrenches are adjustable, allowing them to be used with a wide range of fastener sizes, while others are fixed to a specific size for more specialized use.

Wrenches offer several advantages, including:

-

Leverage: They provide greater torque with minimal effort and are easier to tighten or loosen fasteners.

-

Precision: Wrenches are designed to fit snugly around fasteners, reducing the chance of slipping and damaging the fastener.

-

Durability: High-quality wrenches are often made from chrome vanadium or other hardened steel materials; thus offering excellent durability.

Let’s explore the different types of wrenches and their unique advantages and applications.

1. Combination Wrench

A combination wrench is one of the most commonly used tools in any mechanic's or DIYer's toolbox. This tool combines two types of wrenches into one: an open-end wrench on one side and a box-end wrench on the other. This dual design offers both versatility and convenience so that the users can work with fasteners that might require different approaches.

-

Features: One end of the combination wrench is open, providing quick access to bolts, while the other end is closed or box-shaped, allowing for a more secure grip on fasteners.

-

Advantages: The combination wrench saves space in a toolkit by offering two functionalities in one tool. Its box end provides a firm grip, reducing the chances of rounding off the corners of the bolt or nut.

-

Applications: Ideal for automotive repair, plumbing, and machinery maintenance, this wrench can be used in tight spaces and on fasteners that need a high degree of torque.

-

Procurement Tip: When sourcing combination wrenches, consider sets that cover a wide range of sizes to ensure comprehensive coverage for various maintenance needs.

2. Double Open-End Wrench

A double open-end wrench features open ends on both sides, each typically designed for a different size of fastener. This wrench is especially useful for situations where you need to apply or remove fasteners without obstruction, as the open end allows for quick positioning around the fastener.

-

Features: Both ends are open and angled, usually at 15 degrees, which allows for easier access in tight spaces. The double end provides two different size options in one tool.

-

Advantages: The open ends make it simple to engage fasteners without needing to reposition the wrench multiple times. It’s also very portable, as one wrench can serve multiple purposes.

-

Applications: This type of wrench is widely used in construction, plumbing, and general mechanical work where fasteners need to be turned quickly.

-

Procurement Tip: Look for sets with incrementally sized ends to maximize utility across different fastener sizes commonly used in your facilities.

3. Flare Nut Wrench

Flare nut wrenches are designed specifically for working with soft metal fittings, such as those used in hydraulic or plumbing systems. These wrenches have a design similar to box-end wrenches but with a slight opening to slide over the flare fitting without damaging it.

-

Features: The head of a flare nut wrench has an opening that fits over tubing, making it perfect for gripping soft fittings without stripping or damaging them.

-

Advantages: The wrench’s unique design allows for a strong grip on fasteners while protecting the integrity of the fitting. This is especially important when working with brass or copper fittings.

-

Applications: Flare nut wrenches are commonly used in plumbing and automotive work, particularly when dealing with brake lines, fuel lines, and other soft-metal applications.

-

Procurement Tip: Ensure the material and finish of these wrenches are suitable for the specific metals they'll be used with to prevent galvanic corrosion.

4. Double Ring Wrench

A double ring wrench, also known as a box-end wrench, has two closed, ring-shaped ends. These wrenches are used to apply greater torque and are ideal for working with fasteners in high-stress environments.

-

Features: Both ends are circular, providing an enclosed grip around a nut or bolt. This gives the user excellent control and minimizes the risk of slippage.

-

Advantages: The wrench’s closed design helps to apply torque evenly around the fastener, reducing the risk of rounding it off. It's ideal for situations where a strong grip is necessary.

-

Applications: Commonly used in automotive repair, heavy machinery maintenance, and mechanical assembly, double ring wrenches are perfect for situations requiring high torque applications.

-

Procurement Tip: Invest in high-quality alloy steel variants for these wrenches to ensure longevity in high-stress applications.

5. Half-Moon Wrench

Half-moon wrenches, or curved wrenches, have a distinct crescent shape that enables them to access hard-to-reach fasteners in confined spaces. Their unique design provides access to fasteners that would otherwise be inaccessible with a standard wrench.

-

Features: The curved shape of the wrench allows it to maneuver around obstacles that a straight wrench cannot. It typically has box-ends on both sides for a secure fit.

-

Advantages: The curved design is excellent for working in tight, recessed areas. It gives access to fasteners behind pipes, hoses, or other obstructions.

-

Applications: Half-moon wrenches are especially useful in automotive and machinery maintenance, where fasteners are often placed in hard-to-reach areas.

-

Procurement Tip: Consider the specific machinery in your facilities when selecting half-moon wrench sets to ensure compatibility with common obstructions.

6. Star Wrench

A star wrench, also known as a Torx wrench, is designed specifically for fasteners with a star-shaped pattern. These fasteners are commonly used in automotive and electronic devices where high torque is required without stripping the fastener head.

-

Features: The star-shaped head fits snugly into the corresponding fastener, allowing for greater torque without risk of slippage.

-

Advantages: Star wrenches provide a superior grip compared to standard hex wrenches, making them ideal for precision work and preventing damage to the fastener head.

-

Applications: Widely used in the automotive, electronics, and aerospace industries, star wrenches offer an excellent grip for high-torque applications on specialized fasteners.

-

Procurement Tip: Stay updated on the latest fastener trends in your industry to ensure your star wrench inventory remains relevant and comprehensive.

7. Half-Moon Star Wrench

A half-moon star wrench combines the curved design of the half-moon wrench with the star-shaped head of a Torx wrench. This specialized tool is designed for applications that require both precision and access to awkwardly positioned fasteners.

-

Features: It has a crescent-shaped body with star-shaped ends that provide excellent grip and torque. This allows the tool to be used in confined spaces while still delivering powerful performance.

-

Advantages: The tool’s unique combination of features allows it to access hard-to-reach fasteners while still providing a strong grip on star-shaped fasteners.

-

Applications: Common in automotive repair and specialized machinery maintenance, this tool is useful for fasteners in awkward or recessed locations that require precision handling.

-

Procurement Tip: Assess the frequency of encountering recessed star-shaped fasteners in your operations to determine the necessity and quantity of these specialized tools.

8. Extra Long Star Wrench

The extra-long star wrench is designed to provide additional reach for fasteners located in deep or recessed areas. The long handle allows for greater leverage, making it easier to loosen or tighten stubborn fasteners.

-

Features: With an extended shaft and a star-shaped end, this wrench offers a combination of reach and precision. The star pattern ensures a strong grip on fasteners.

-

Advantages: The extended length provides excellent leverage, making it easier to work on fasteners in deep or tight spaces. It also reduces the need for excessive force, reducing the risk of damaging the fastener.

-

Applications: This wrench is ideal for automotive work, particularly in areas like engine compartments or other confined spaces where fasteners are difficult to reach.

-

Procurement Tip: Consider the depth of access required in your specific machinery when selecting the length of these wrenches.

Wrenches are invaluable tools in various industries, each serving a unique purpose depending on its design. Whether working in an industrial setting, performing mechanical repairs, or simply handling tasks at garages, choosing the right wrench can make a significant difference in the ease and success of the job. From the versatile combination wrench to the specialized extra-long star wrench, each tool offers specific advantages that cater to different tasks and scenarios. Understanding the differences between these wrenches ensures that you have the right tool for every job, enhancing both efficiency and safety in your work.

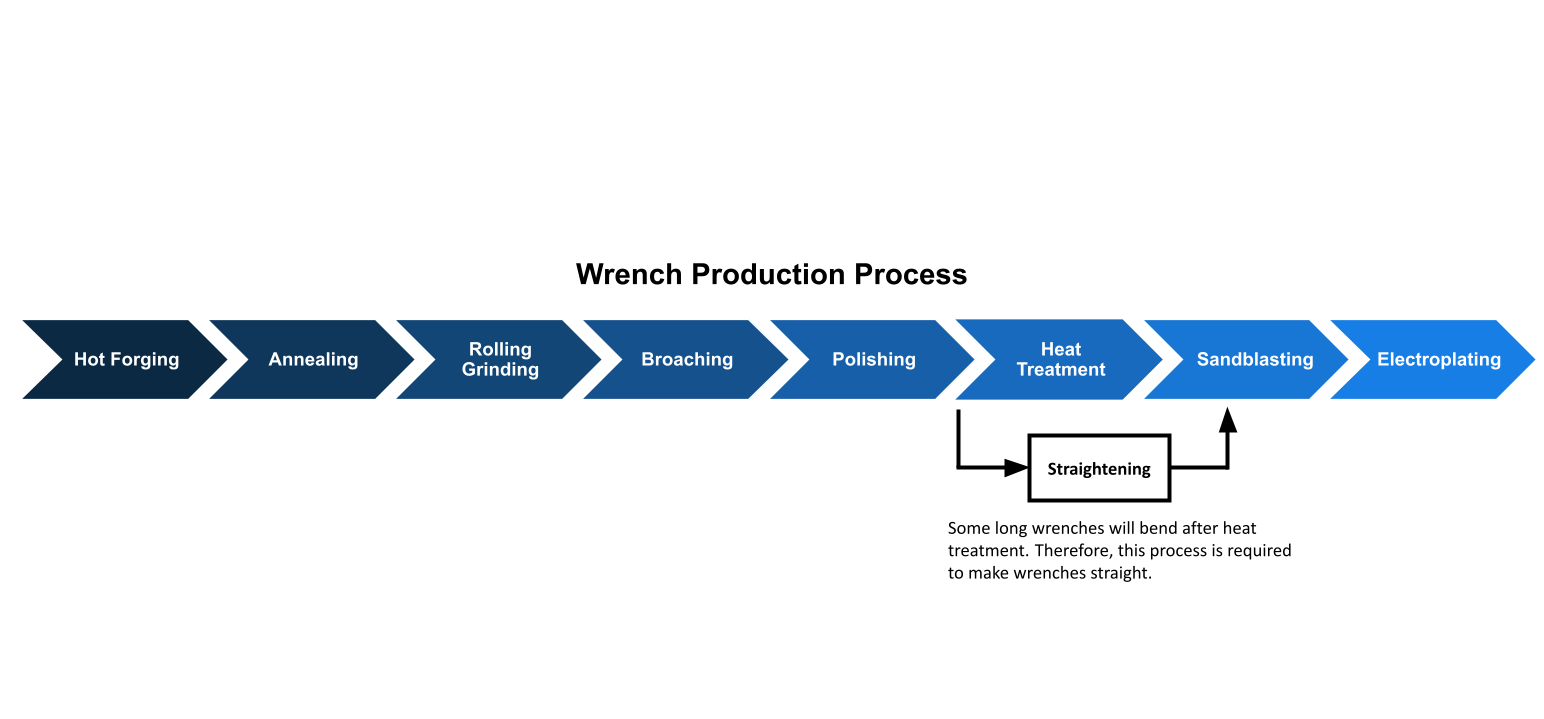

At EUREKOR, wrenches are the top opted tools owing to the quality, competitive pricing, and the various usages. Our products are mostly made with durable materials such as Chrome Vanadium Steel. The typical manufacturing process is as below.

Contact us to learn more about our wrenches and discuss how these products can add value to your work.

You might also be interested in:

- Mastering Automotive Repairs: 3 Essential Tools and Techniques

- Understanding the Differences Between Chrome Vanadium (Cr-V) and Chrome Molybdenum (Cr-Mo) Steel in Hand Tools

- 10 Essential Hand Tools for Repair and Maintenance

- Essential Tips for Hand Tool Procurement: Maintaining Hand Tools in Good Condition

- Hand Tool OEM, ODM, and Owned Brand: Exploring Taiwan’s Role as a Global Leader

- The Top 10 Hand Tools You Should Be Importing from Taiwan